Onsite dilution with various water types

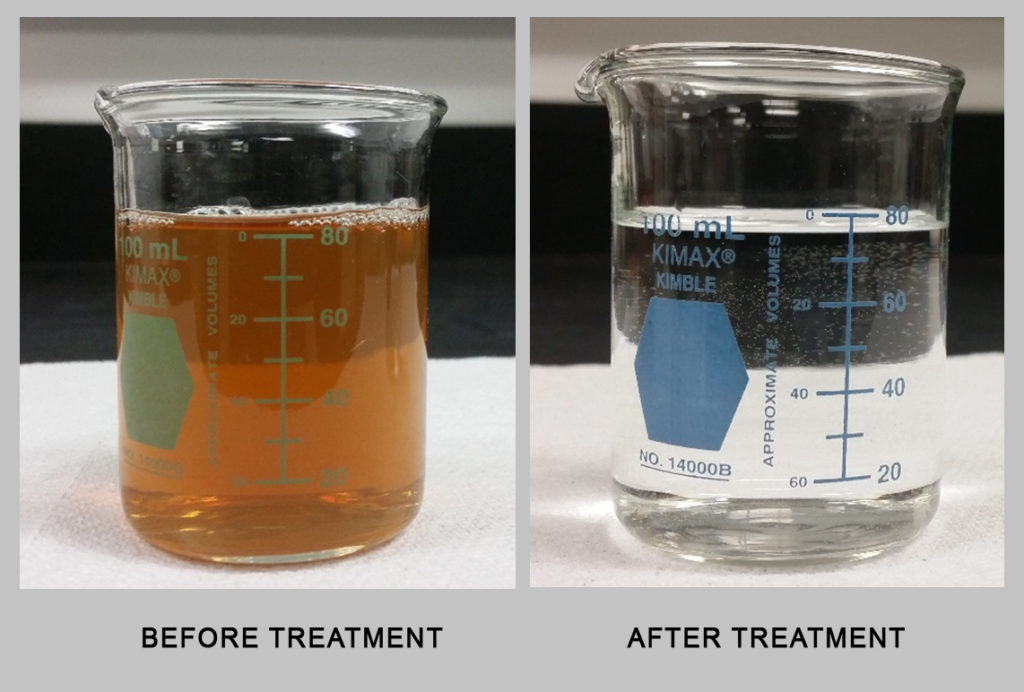

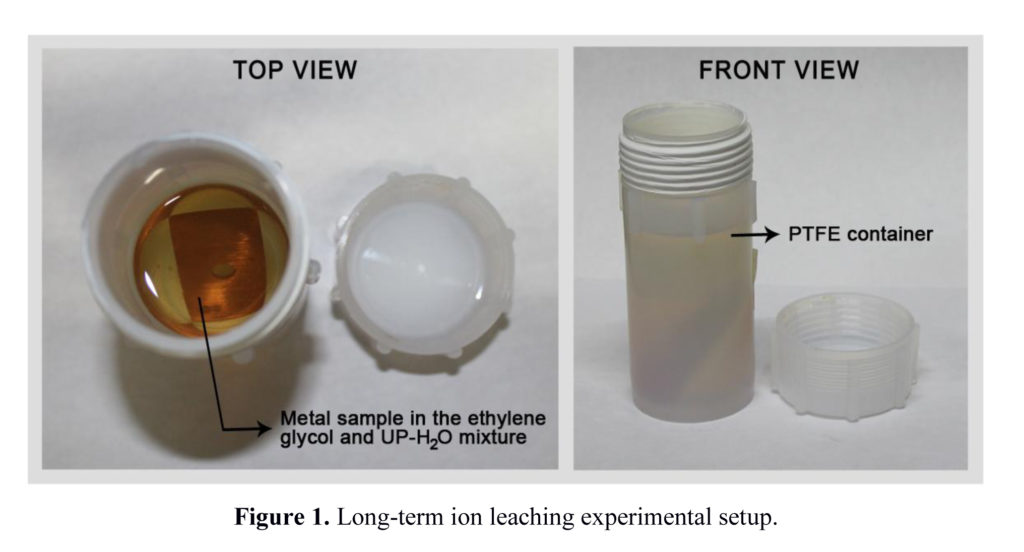

Water for Glycol Dilution: Effect of Water Type on On-site Dilution of Glycol-based Heat Transfer Fluids Water-based heat transfer fluids made from propylene glycol, ethylene glycol, or bio-based glycol are widely used across various applications, including HVAC systems, industrial chillers, process heating and cooling, and data centers. The glycol in these fluids provides critical benefits […]

Onsite dilution with various water types Read More »