Dynalene

| Abstract Sulfate contamination can cause corrosion, which can affect operation and downtime for maintenance. Dynalene’s ion exchange resin can be used to reduce the sulfate concentration to below 1mg/L. |

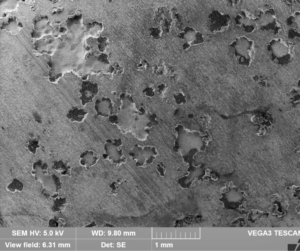

| Introduction Sulfate in fluids used in the industrial application can be corrosive. They can cause scale buildup in the pipes leading to clogging. The Environmental Protection Agency (EPA) has named sulfate as a secondary standard with a max contamination level (MCL) of 250 mg/L in the drinking water. Sulfate contamination can affect the color and taste of drinking water. [1]. The main goal of this study was to see the removal effects of ion exchange resins on a solution containing sulfate and if the ion exchange resin could bring the concentration down to below the 1 mg/L. |

| Background / Experiment · Sample: Aqueous solution of sulfate · Problem: Pipe corrosion and clogging · Initial concentrations: 50 mg/L sulfate standard · Adsorbent / Media: Ion exchange resins (SO-25AX and SO-25MX, Dynalene Inc. Product) |

| Results and Challenges The sulfate concentration after processing the fluid with SO-25AX and SO-25MX ion exchange resin were 0.206 mg/L 0.074 mg/L respectively. The size of the contamination removal system can be custom designed to handle higher flow rates and volume. |

| Conclusion Ion exchange resins SO-25AX and SO-25MX can be used to reduce the sulfate concentration in a solution to less than 1 mg/L. The media can be used for sulfate removal in water and water-based heat transfer fluids. The size of the contamination removal system can be custom designed to meet customer requirements. |

| References [1] Environmental Protection Agency, “Secondary Drinking Water Standards: Guidance for Nuisance Chemicals”, EPA, March 8, 2017. |

Share:

Facebook

Twitter

Pinterest

LinkedIn