Heat Transfer Fluids

Dynalene, Inc. is a US based leading developer and manufacturer of heat transfer fluids, coolants and glycols serving customers all around the world with three manufacturing locations in Pennsylvania, Illinois, and Utah. Through its strong R&D program, the company routinely develops new heat transfer fluid formulations for cooling applications in data centers, electronics, fuel cells, batteries, and electric motors. Dynalene’s line of heat transfer fluids includes high performing glycol-based coolants such as Propylene Glycol, Ethylene Glycol, BioGlycol, Solar Glycol, and liquids manufactured involving innovative and proprietary chemistries such as potassium formate, hydrocarbons, silicone and molten salts. Dynalene fluids are offered in 1, 5, 30, 55, and 265-gallon containers as well as 5,000-gallon tankers. Contact us today at 610.262.9686 or email at info@dynalene.com and let us help you determine the best fluid for your application.

Low Temperature Heat Transfer Fluids

Non-toxic, non-flammable fluid

(-58°F to 425°F) / (-50°C to 218°C)

Food safe heat transfer fluid

(-58°F to 425°F) / (-50°C to 218°C)

Non-toxic, high flash point fluid

(-100°F to 400°F) / (-73°C to 204°C)

Low temperature cryogenic fluid

(-170°F to 325°F) / (-112°C to 163°C)

Non-toxic, low odor heat transfer fluid

(-40°F to 400°F) / (-40°C to 205°C)

Inhibited Calcium Chloride brines

(-40°F to 212°F) / (-40°C to 100°C)

Propylene glycol heat transfer fluids

(-50°F to 350°F) / (-46°C to 177°C)

Ethylene glycol heat transfer fluids

(-60°F to 350°F) / (-51°C to 177°C)

Corn derived glycol heat transfer fluid

(-50°F to 350°F) / (-46°C to 177°C)

Solar thermal heat transfer fluid

(-17°F to 350°F) / (-27°C to 176°C)

Inhibited TEG heat transfer fluid

(-32°F to 400°F) / (-35°C to 204°C)

High Temperature Heat Transfer Fluids

Molten salt heat transfer fluid

(270°F to 1050°F) / (130°C to 565°C)

Silicone open bath fluid

(150°F to 550°F) / (70°C to 288°C)

Synthetic heat transfer fluid

(68°F to 662°F) / (20°C to 350°C)

Synthetic heat transfer fluid

(32°F to 662°F) / (0°C to 350°C)

Synthetic heat transfer fluid

(32°F to 600°F) / (0°C to 315°C)

Low odor, non-toxic heat transfer fluid

(32°F to 400°F) / (0°C to 205°C)

Low Electrical Conductivity Heat Transfer Fluids

Glycol-based low electrical conductivity heat transfer fluids for fuel cell and electronics cooling applications

Nanoparticle-based low electrical conductivity heat transfer fluids for fuel cell cooling applications

Flushing Fluid Series

Water-based flushing fluid formulation designed to remove debris, machine grease, lubricant, corrosive residue, and other foreign matter from your system prior to installing a new Dynalene heat transfer fluid.

Use Our Fluid Property Calculator to Calculate the Properties of Dynalene Fluids.

Questions About Heat Transfer Fluids

A heat transfer fluid (HTF) is a liquid or a gas that transports heat from one component to another component in any process requiring heating or cooling or simply to maintain a constant temperature. The desirable attributes of a heat transfer fluid are non – or low toxicity (sometimes food grade or food safe), low viscosity at low temperatures, high specific heat and thermal conductivity, environmentally friendly, high flash point (or non-flammable/non-combustible in some cases) and economical.

Here are some examples of processes requiring an HTF are: cooling of a reactor with an exothermic reaction, maintaining a very low-temperature climactic chamber or wind tunnel, utilizing solar energy to make hot water, cooling an engine block, maintaining the ice temperature in an ice rink, cold storage and cooling high power electronics.

In general, HTFs can be classified into (1) low temperature, (2) medium temperature (glycols) and (3) high-temperature fluids. Low-temperature fluids are normally used below 32ºF (0ºC) down to about -148ºF (-100ºC). The chemistries that are used as low-temperature heat transfer fluids are salt brines, hydrocarbons and silicone oils. Glycols such as propylene glycol (PG), ethylene glycol (EG) and 1,3 propanediol (Bioglycol) are used for freeze protection below 32ºF and can be used up to 350ºF with a proper additive package. High-temperature fluids are normally used above 350ºF up to 662ºF (350ºC).

Dynalene heat transfer fluids cover a very wide range of usage temperature, from as low as -112°C (-170°F) to as high as 565°C (1050°F). Dynalene’s customers range from Fortune 500 companies building large industrial complexes to small businesses servicing residential HVAC systems. Dynalene also provides laboratory testing services including heat transfer fluids and glycol testing, thermo-physical properties and quality control.

Fluid Focus

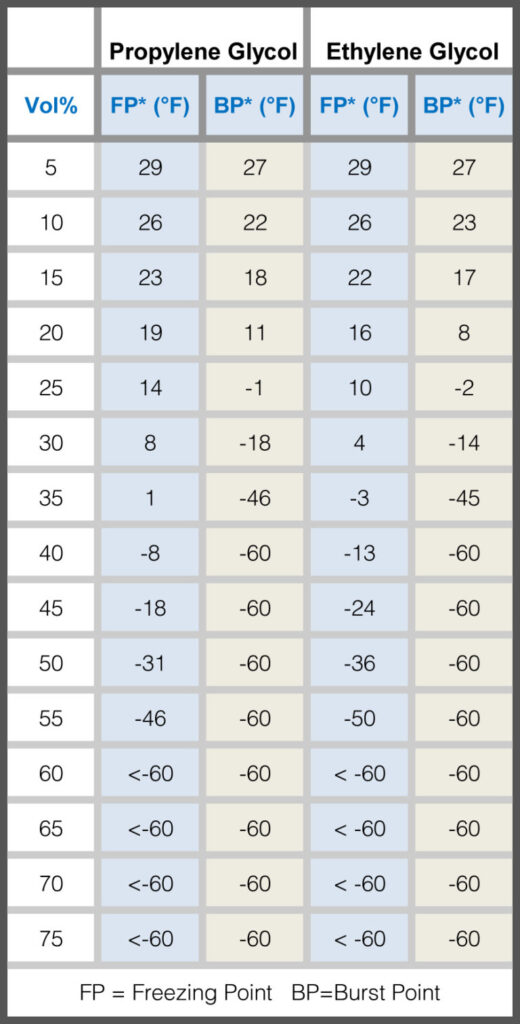

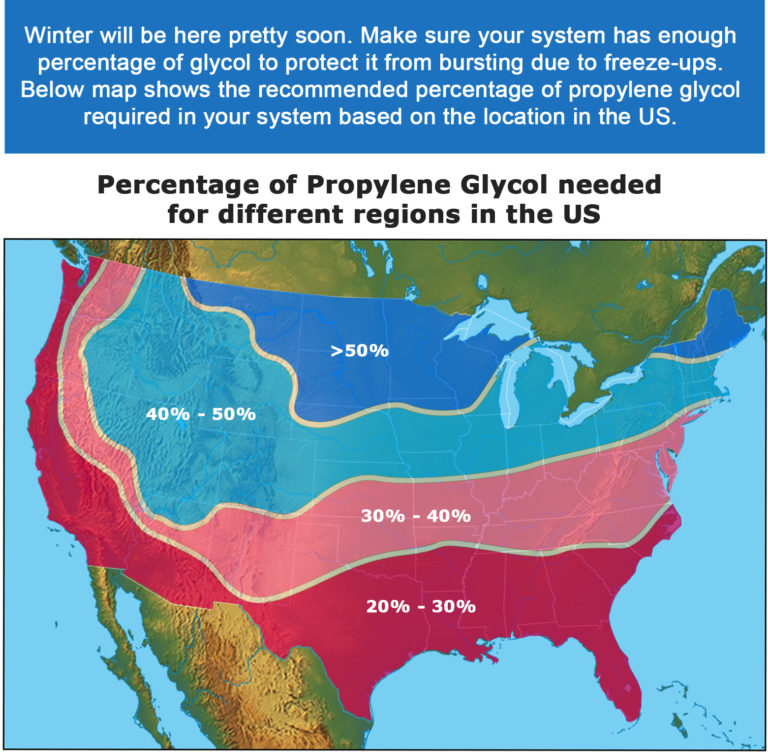

Ready for winter? Check the freezing point and the bursting point of your glycol!

When using glycol/water mixtures in your heat transfer fluid system, it is important to consider how cold the fluid will get, but it is also equally important to consider how the fluid will be used at that temperature. Will the fluid be stagnant or will it be circulated? Is the glycol for winterization? These questions ultimately affect the mixture ratio of the glycol. For example, if a coolant loop or system is being winterized and temperatures will fall down to -10°F at the lowest, a mixture of 30% propylene glycol to 70% water will be enough to protect the system. 30% propylene glycol has a freeze point of 8°F but the burst point is -18°F. This system will be protected but the coolant will be slushy. By definition, freezing point is the temperature where ice crystals begin to form. The fluid will become slushy but will not expand. The burst point of a fluid is the temperature where the fluid will freeze solid, expand, and break pipes or damage other parts of the equipment.