Dynalene

Contributed by:

Bojanna Shantheyanda, Dynalene Inc | Email: boji@dynalene.com

Ricardo Gonzalez, Gill Ranch Storage LLC

1. Abstract

Salt-rich water infusion from underground storage to the dehydration system during gas withdrawal can increase the salt contamination in the triethylene glycol (TEG). The increase in salt contamination in TEG can lead to an increase in corrosion of the metal piping, create hot spots in the fire tubes and decrease the moisture removal efficiency of the dehydration system. These contaminants can be easily and economically removed from the TEG fluid using ion exchange based Contamination Removal System (CRS). This case study discusses the results of a contamination removal project carried out at a natural gas storage station. The report also includes discussion about the operational and economical benefits of using the ion exchange method for contamination removal.

2. Introduction

Natural gas is usually stored underground, in large storage reservoirs. There are three main types of underground storage: depleted gas reservoirs, aquifers, and salt caverns. Though most of the storage in the United States is a depleted gas reservoir, the ability to perform several withdrawal and injection cycles each year provide salt caverns a unique advantage over rest of the storage techniques [1].

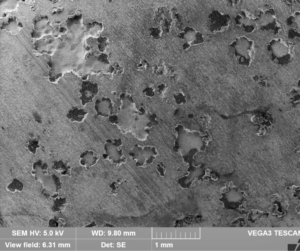

Natural gas, when withdrawn from the underground storage reservoirs, contains moisture; therefore, TEG dehydration towers are used to remove moisture from the natural gas. The moisture in the natural gas contains earthly salts and minerals such as chlorides, silica, sulfate, iron, and others. These salts and the minerals remain in glycol after water is removed through reboiling. Over time, the concentration of the salts increases in the glycol fluid leading to several efficiencies and technical related issues. Higher concentration of chloride in the TEG can cause corrosion of the equipment, create hot spots on the fire tube, increase glycol degradation, increase chances of clogging, lower pH and decrease the dehydration efficiency, leading to periodic glycol change-out [2].

The increase in salt concentration in the TEG can be predominantly noticed in salt cavern based natural gas storage stations. Storage sites also experience an increase in salt concentration in the TEG during an unexpected increase in moisture infusion during withdrawal. The moisture may travel all the way to the dehydration system due to malfunctioning of the slug catcher and coalition filters.

Ion exchange process can be used to remove the ionic salt contaminants and bring the contaminant level below the acceptable level. In an ion exchange process, a chemical reaction is used to remove the dissolved salt ions in the TEG and the unwanted ions in the fluid is replaced with similarly charged ions from ion exchange media. Due to simple operational technique, the ion exchange based glycol reclamation can be carried out while the plant is operational and does not require handling of the caustic solution.

3. Contamination removal project at Gill Ranch Storage, CA

i. Background:

The project was carried out at Gill Ranch Storage facility, which is a wholly owned by NW Natural and PG&E Corporation. The storage is an underground intra-state facility near Fresno, California and has the capacity to provide approximately 20 billion cubic feet (Bcf) of underground natural gas storage.

Table 1: lists of fluid parameters and site conditions during and before the project. Table 1 lists the TEG fluid parameters and site conditions during the project. The chloride level in the TEG had increased to 2486.3 ppm due to the unexpected infusion of moisture into the dehydration system during the withdrawal of the natural gas. The moisture managed to pass through the slug catcher and coalition filter and reach the dehydration system and the presence of earthy salts in the moisture results in the increase of chloride level above the desired level which is less than 100 ppm.

Some of the other requirements that had been taken into account during the proposal of the contamination removal system were:

- Avoid using electrical power or any source that can cause a spark.

- Establishing a process that will not require handling chemical, caustic solution or any components that may create an explosion in the operation site.

- Contamination removal process that does not require the collection and disposal of the waste byproduct in the natural gas site.

- Easy handling and simple operational procedure that will require minimum monitoring by operation personnel.

i. Process setup and parameters

Figure 1 shows the CRS setup that was implemented at the Gill Ranch storage site. 5 micron filter was installed to remove the particulate contaminants in the glycol fluid both at the inlet and the outlet of the CRS. The TEG from the TEG storage tank is connected to the filtration skid and then to the CRS. After the contamination removal, the TEG is passed through the filtration skid before putting it back to the TEG storage tank. Additional CRS was connected in parallel for higher throughput. Based on the project requirement, the CRS was designed with the following capabilities.

- Pallet mounted system that can be moved using a forklift.

- On-site chloride removal solution that can be connected to the dehydration system without needing to transport the fluid away from the site.

- 10 to 15 gallons per minute fluid reclaiming capability. The flow rate capability can be increased by connecting additional CRS skids in parallel.

- Equipped with 5 micron particulate filters both at the inlet and the outlet of the CRS.

- 2” camlock connectors for the fluid inlet.

- Accessible sample ports at the inlet and outlet of the CRS.

- Foot print of the system:

Ion exchange skid: 48 inch x 48 inch x 74 inch (length x width x height)

Filtration skid: 48 inch x 48 inch x 36 inch (length x width x height)

i. Results and discussion

Table 2: Chloride content in the TEG during the contamination removal process using CRS. Approximately 7500 Gallons of TEG was circulated through the CRS filters and samples of initial and final TEG is reported in Table 2. The chloride content measured at the site using HACH Chloride QuanTab® Test Strips. In order to verify the results obtained in the field, Metrohm 761 Compact Ion Chromatography equipment was used to measure the chloride content of the TEG at the Dynalene laboratory.

The fluid samples were taken both at the (V1) inlet and the outlet (V7) of the CRS and the chloride levels were tested. The chloride levels in the TEG tank dropped steadily to reach 75.6 ppm in 46 hours. Figure 2 shows the samples that were collected during the contamination removal project at the Gill Ranch Storage. The image also shows the HACH stripe analysis that was performed at the site.

4. Cost analysis and value

The functional and economic value of the ion exchange-based contamination removal is discussed below. The economic value includes discussion about the cost analysis for a plant similar to Gill Ranch Storage. Figure 3: Cost comparison of purchasing TEG compared to reclaiming TEG using CRS. The cost of purchasing virgin TEG is calculated based on the current market pricing.

a. Functional value

- The TEG reclamation can be achieved while the dehydration system is operational by connecting the CRS in a slip stream. The contamination removal does not require the fluid to be transported offsite for reclamation.

- Along with chloride removal, the CRS can also be extended to remove other ionic salt contaminants such as sodium, iodide, sulphate, nitrate, phosphate, potassium, molybdate and selenium, arsenic etc,.

- The contamination removal operation does not require handling of caustic solution or disposal of hazardous waste.

b. Economical value

- Continuous contamination removal can help avoid plant shutdown due to high chloride levels in the TEG.

- Reclaiming the glycol at the site can help prolong the life of the TEG. Hence reducing the operational cost by avoiding regular fluid replacement.

- Keeping the fluid free of ions that cause corrosion can help reduce the equipment service cost.

Figure 3 compares the current market price of TEG and the cost of reclaiming TEG using the CRS system. The cost of the TEG reclamation is estimated for the system comparable fluid properties at the Gill Ranch site during the time of the project. The TEG cost is calculated based on the current market price trend. For similar project as that of the Gill Ranch Storage, using CRS for onsite TEG reclamation may provide about 38% cost saving compared to purchasing virgin TEG. For a project with about 600 ppm chloride contamination, TEG onsite reclamation using CRS may provide more than 50% cost savings. Figure 4: The change in the cost of TEG per pound and the total cost of purchasing of 7,500 gallons of TEG in the last two years.

The growth of the global natural gas market and rising demand for plasticizers across industries has led to an increase in demand for TEG. However, unpredictable fluctuations in the prices of raw materials and stringent regulatory concerns associated with the production and use of TEG has led to a volatile market [3]. Additionally, the high capital cost involved in producing higher derivatives of glycols and the rising demand for lower derivatives of ethylene glycols such as monoethylene glycol (MEG) and diethylene (DEG) is expected to pose a credible threat to the TEG market [4]. Figure 4 shows the change in the cost of TEG per pound and the total cost of purchasing 7,500 gallons of TEG in the last two years. With the recent trend of allocation of TEG to larger jobs, long term prediction of the price and availability has been difficult.

5. Conclusion

Ion exchange based contamination removal technology was successfully implemented in a natural gas storage site to bring the chloride level below the acceptable level of 100 ppm. The contamination removal using the CRS could be achieved while the dehydration system was operational, without needing to transport TEG offsite. In addition to chlorides, the ion exchange process can be used to remove most of the ionic salt contaminants without requiring handling of caustic solution or disposal of hazardous waste. In a volatile TEG market, using CRS system for glycol reclamation may provide more than 50% cost savings compared to purchasing virgin TEG.

6. References

- S Energy Information Administration “The Basics of Underground Natural Gas Storage” Release Date: November 16, 2015.

- Gas Processors Suppliers Association Handbook(2008), 10th

- “Growing Demand for Natural Gas and Plasticizers to Boost Demand for Triethylene Glycol in the Global Market”, Transperancy market research, Feb, 2015.

- “Triethylene Glycol (TEG) Market Analysis By Application (Natural Gas Dehydration, Solvents, Plasticizers, Polyurethanes, Humectants, Polyester Resins) And Segment Forecasts To 2022” Grand View Research, Report ID: 978-1-68038-382-9, Apr, 2016.