Case Study and Laboratory Reports

Contamination Removal

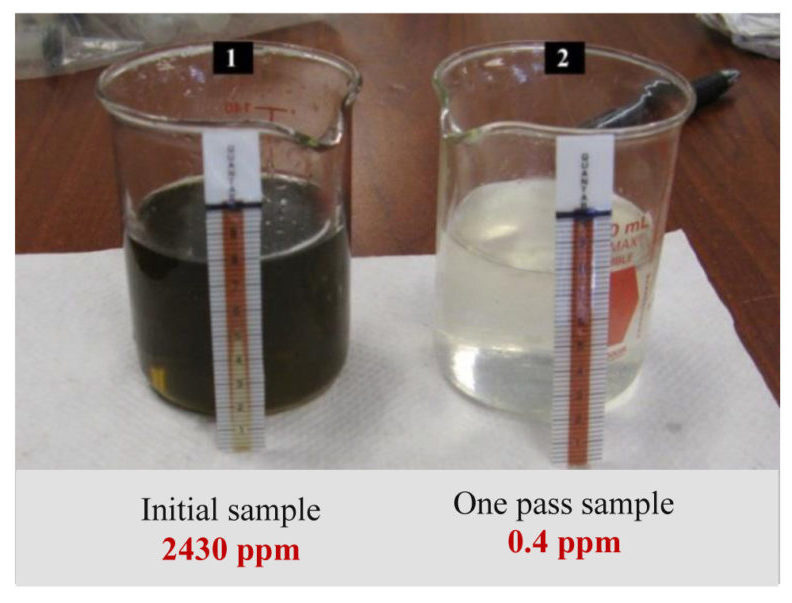

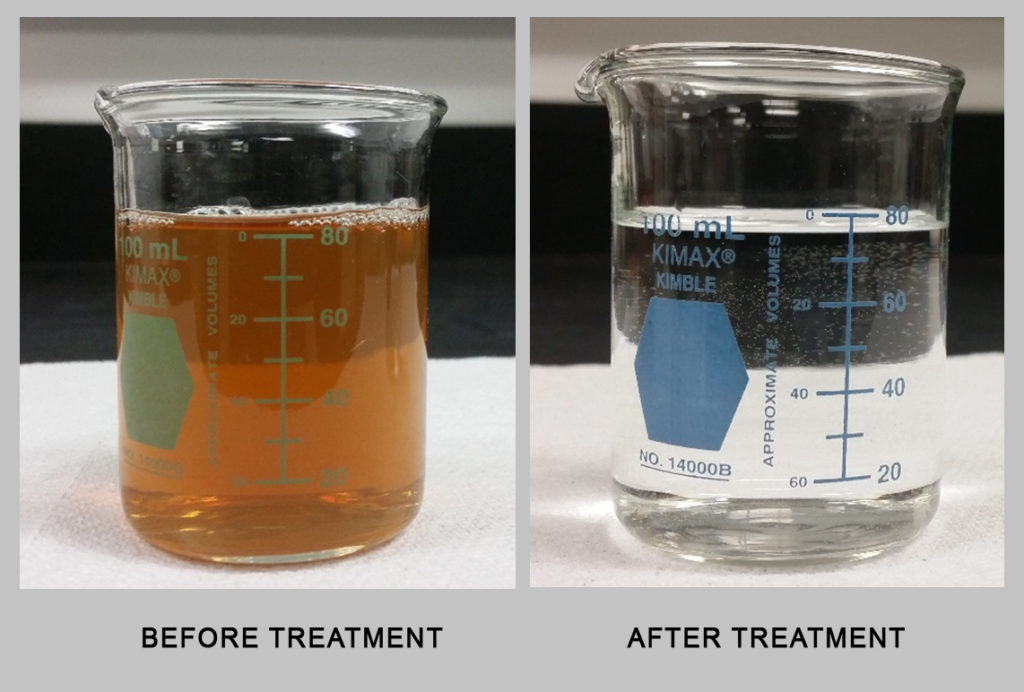

Abstract: Salt-rich water infusion from underground storage to the dehydration system during gas withdrawal can increase the salt contamination in the triethylene glycol (TEG). The increase in salt contamination in TEG can lead to an increase in corrosion of the metal piping, create hot spots in the fire tubes and decrease the moisture removal efficiency of the dehydration system. These contaminants can be easily and economically removed from the TEG fluid using ion exchange based Contamination Removal System (CRS). This case study discusses the results of a contamination removal project carried out at a natural gas storage station. The report also includes discussion about the operational and economic benefits of using the ion exchange method for contamination removal.

Abstract:

Vanadium (V) and nickel (Ni) are an industrial toxic waste which endangers the productivity and life of plants, crops, and the whole agricultural system. In this case study, V and Ni removal from the water (V concentration=4.5 mg/L and Ni concentration=0.85 mg/L) which is obtained from an industrial wastewater treatment facility is discussed. The main goal of this study was to develop a method for efficient removal of V and Ni from industrial wastewater simultaneously. The lowest achieved V and Ni concentrations using the contamination removal process were 0.024 and 0.033 mg/L, respectively.

Abstract:

Lead contamination is most commonly found in drinking water. Activated carbon was used to reduce the concentration of lead in an aqueous solutions to less than 7.8 µg/L.

Abstract:

Low concentrations of selenium (Se) in elemental form is relatively safe for drinking water and aquatic life, however elemental selenium and its compounds are toxic in high dosages [1]. The removal of selenium was investigated using two different ion exchange resins. Dynalene’s ion exchange resin was able to reduce the selenium to below 4.5 µg/L.

Abstract:

Sulfate in fluids used in the industrial application can be corrosive. They can cause scale buildup in the pipes leading to clogging. The Environmental Protection Agency (EPA) has named sulfate as a secondary standard with a max contamination level (MCL) of 250 mg/L in the drinking water. Sulfate contamination can affect the color and taste of drinking water. Ion exchange resins SO-25AX and SO-25MX can be used to reduce the sulfate concentration in a solution to less than 1 mg/L. The media can be used for sulfate removal in water and waterbased heat transfer fluids.

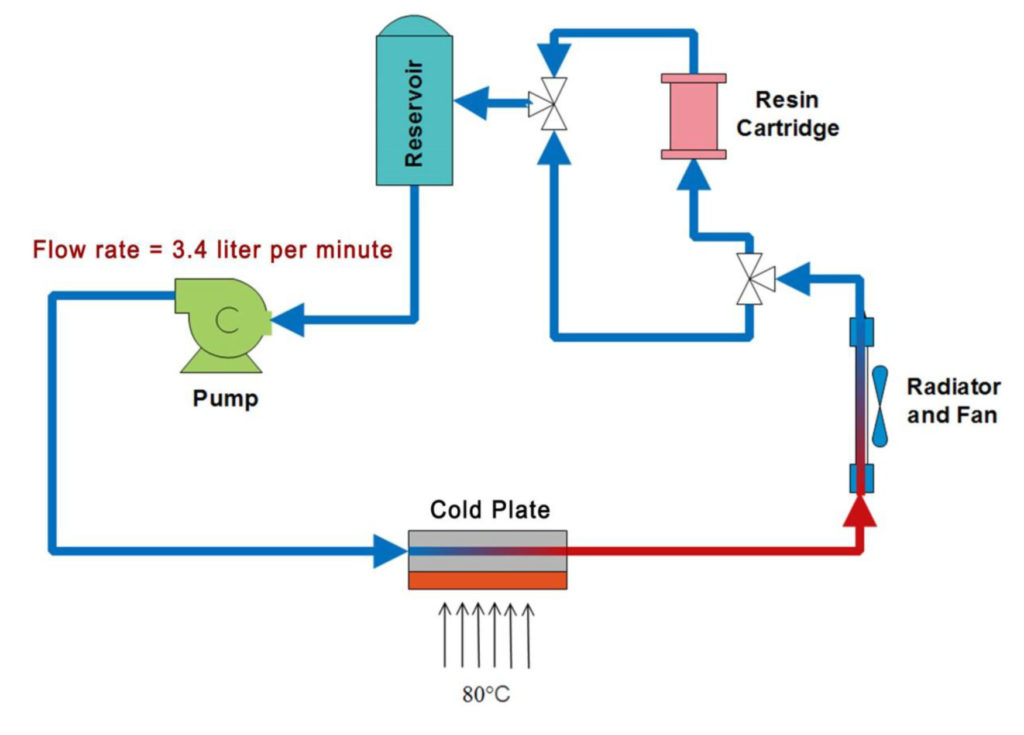

Abstract: Ion exchange resin can be used to remove the ionic substances that raise the electrical conductivity of the coolant in an electronics cooling application. In this study, ion leaching tests were performed with various metals and polymers in both ultrapure deionized (DI) water, i.e. water which is treated to the highest levels of purity, and low electrical conductive ethylene glycol/water mixture, with the measured change in conductivity reported over time. Additionally, changes in the electrical conductivity of ultrapure DI water in an indirect, single phase, active cooling loop, with and without ion exchange resin are characterized with the findings reported. Finally, recommendation for the design and estimation of the longevity of the ion exchange resin cartridge in an electronics cooling loop is discussed.