Dynalene

How do you choose a glycol?

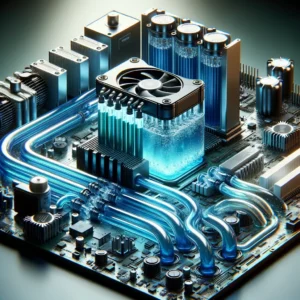

Glycols are used in many different process cooling and heating applications: HVAC systems, ice rinks, food and pharmaceutical processes, plastic molding, and solar thermal heat transfer. There are two main types of glycols: ethylene glycol and propylene glycol.

The number one difference between the two glycols is that ethylene glycol is toxic and propylene glycol is not, allowing propylene glycol to be purchased as food grade in addition to the technical or industrial grade.

The two glycols also have differences in their physical properties. Propylene glycol solutions have higher viscosity and higher freezing point than ethylene glycol at the same percentage, causing it to be less thermally efficient than ethylene glycol, especially at lower temperatures. Propylene glycol is also more expensive than ethylene glycol.

To illustrate this, compare the properties of 50 volume % propylene glycol versus ethylene glycol. 50% propylene glycol has a freezing pointof -31°F, where 50% ethylene glycol freezes at -36°F. The viscosity of that propylene glycol solution is 96 centipoise at -10°F, and the ethylene glycol will be 27 centipoise at the same temperature. This means that ethylene glycol can be used at temperatures roughly 20 degrees lower than propylene glycol.

For these reasons, ethylene glycol is commonly used in applications where efficiency is important and there is no human or animal contact, such as ice rinks, plastic molding, and in-line heaters. Ethylene glycol is the predominant fluid used for automotive antifreeze formulations. Propylene glycol is used in food and pharmaceutical applications, and HVAC systems in schools, homes, and businesses – anywhere there is a risk of human or animal exposure.

To determine which glycol is most appropriate for your system, all these factors should be taken into consideration: type of application, toxicity, thermal efficiency, and cost. There is no one-size-fits-all solution when it comes to constructing a heat transfer system, and you should make your choice of fluid thoughtfully and carefully.