Ion Exchange

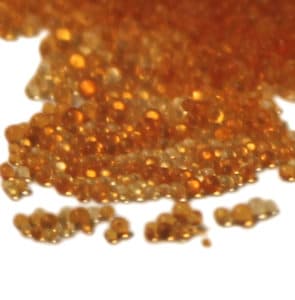

The IC and EC series ion exchange resin cartridges offered by Dynalene can be used to maintain low conductivity in fuel cell cooling, battery cooling, electronic cooling and computer cooling applications.

Dynalene has experience in using ion exchange resin in contamination removal applications for various industries. We can also offer systems to remove other contaminants, such as chloride, molybdate, selenium, arsenic, calcium, sulfate, magnesium and phosphate, in both water and glycol based fluids.

Dynalene has experience in using ion exchange resin in contamination removal applications for various industries. We can also offer systems to remove other contaminants, such as chloride, molybdate, selenium, arsenic, calcium, sulfate, magnesium and phosphate, in both water and glycol based fluids.

Dynalene offers contamination removal systems that can remove both particulate and ionic contaminants in glycol-based heat transfer fluids. These systems can be used in a slipstream or in the main loop for continuous contamination removal without having to stop the existing process.

Dynalene’s ion exchange resin products are designed and tested to be used in softening, deioninzation and low conductivity applications.

Low conductivity products can be used in maintaining low conductivity in fuel cell cooling, battery cooling, electronic cooling and computer cooling applications. They are designed and tested extensively for greater ion removal on low conductivity heat transfer fluid products including, our Dynalene LC and FC series heat transfer fluid products. The cartridges can be easily installed in systems operating up to 200°F (93°C).

Contamination removal products offered by Dynalene are capable of removing contamination from water, glycols and hydrocarbon-based fluids. These products can be designed to remove contaminants such as chloride, molybdate, selenium, arsenic, calcium, sulfate, magnesium and phosphate, in both water and glycol based fluids.

Water softening products are designed to reduce hardness in water by efficiently removing calcium and magnesium compounds in commercial and industrial applications. These systems help eliminates scaling in piping, process equipment, and heat exchange systems. These softening system helps improve the effectiveness of cleaning and rinsing processes.

Water deionization system offered by Dynalene are designed to remove such as cations like sodium, calcium, iron, and copper, and anions such as chloride and sulfate. These system are ideal for use in medical, food processing, chemical and semiconductor industry including, industrial cooling applications and manufacturing of cosmetics. The DYI series systems are also ideal for in-site DI water making to be blended with glycol to make a glycol-water solution. These system can be offered for the flow rate of 1 to 10 GPM and can be custom designed to cater to your requirement.

Glycol regenration systems offered by Dynalene can remove both particulate and ionic contaminants in glycol-based heat transfer fluids such as propylene glycol, ethylene glycol, and triethylene glycol. These systems can be used in a slipstream or in the main loop for continuous contamination removal without having to stop the existing process. Dynalene’s systems can remove ionic contamination such as chloride, molybdate, calcium, magnesium, sulfate, acetate, selenium, arsenic, and more.

Our custom designed ion exchange resin based products are being tested in various niche contamination applications. Some of them being chloride removal from triethylene glycol (TEG) and contamination removal from some proprietary engineering fluids. Contact us today at 610.262.9686 or email at info@dynalene.com and discuss your application with Dynalene’s fluid experts.