Carter Prokesch

Senior R&D Engineer

There are many types of coolants used for immersion cooling of IT equipment in data centers. These coolants can be hydrocarbon-based, esters (natural or synthetic) or fluorocarbons. Depending on their properties, they may be used in single-phase immersion or two-phase immersion. This article will discuss the main property considerations for coolants used in data center immersion cooling and provide a useful comparison of each chemistry to aid in fluid selection.

When deciding on a coolant to use, the following properties are important [1] [2]:

- Dielectric Properties – if the fluid is going to be in direct contact with electronics, it must have sufficient dielectric properties. These include dielectric strength (> 6 kV/mm), breakdown voltage, and volume resistivity (> 2.00 GΩ.m).

- Thermal Performance – the thermophysical properties, mainly viscosity, thermal conductivity, specific heat capacity, and density need to be accounted for to ensure proper thermal management design. In two-phase applications, boiling point and latent heat of vaporization also need consideration.

- Stability – the fluid adequately maintains its properties under a wide range of conditions. Properties reflective of chemical stability include thermal stability, oxidative stability, and hydrolytic stability. Volatility is a way to assess physical stability and is often cited in single-phase immersion cooling.

- Safety – toxicity toward humans and other living things and flammability, notably flashpoint (> 150°C) and autoignition point (300°C) are crucial in fluid selection.

- Environmental Impact – biodegradability, global warming potential (GWP), and ozone depletion potential (ODP) are important properties to know when choosing a sustainable coolant. Coolants with high biodegradability, low GWP, and low ODP are more environmentally friendly.

- Compatibility – the fluid must have acceptable compatibility with the metals and polymers it will be exposed to, must not interfere with function of mechanical equipment, and must not disrupt signal transmission. Some common materials exposed to immersion coolants include PVC or nitrile clad cables and EPDM, liquid crystal polymer, PTFE and fluoroelastomer connectors and seals.

- Maintenance and Handling – fluids vary in their filtration, containment, and PPE requirements. The lifetimes of fluids vary as well, which can affect replacement or top-off frequency. The fluid color and odor can further complicate maintenance and handling procedures.

- Cost – price differs significantly and is highly dependent on the base fluid chemistry.

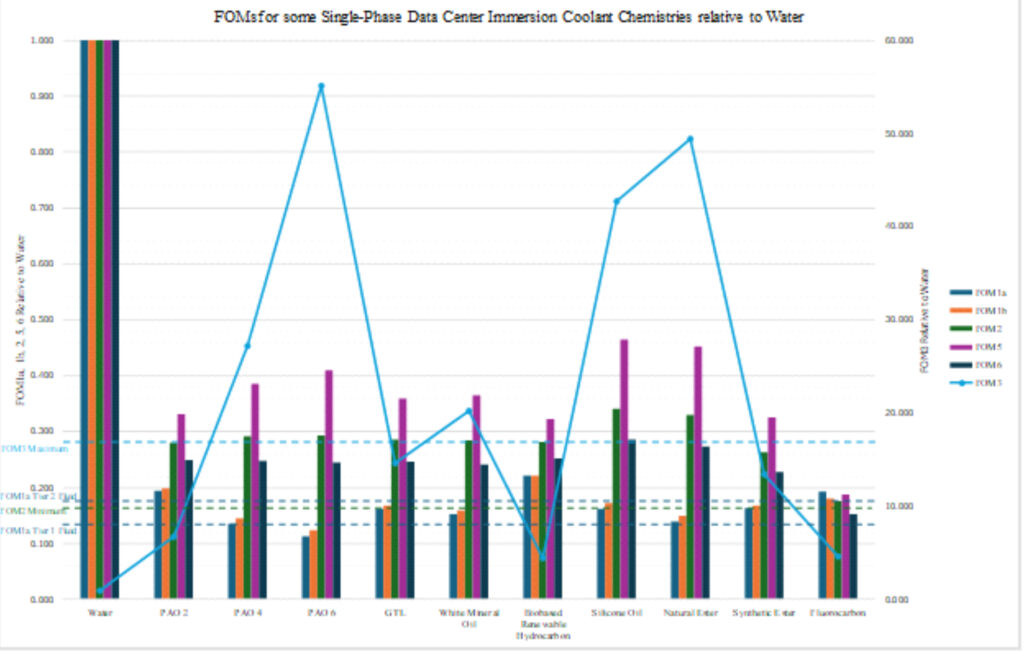

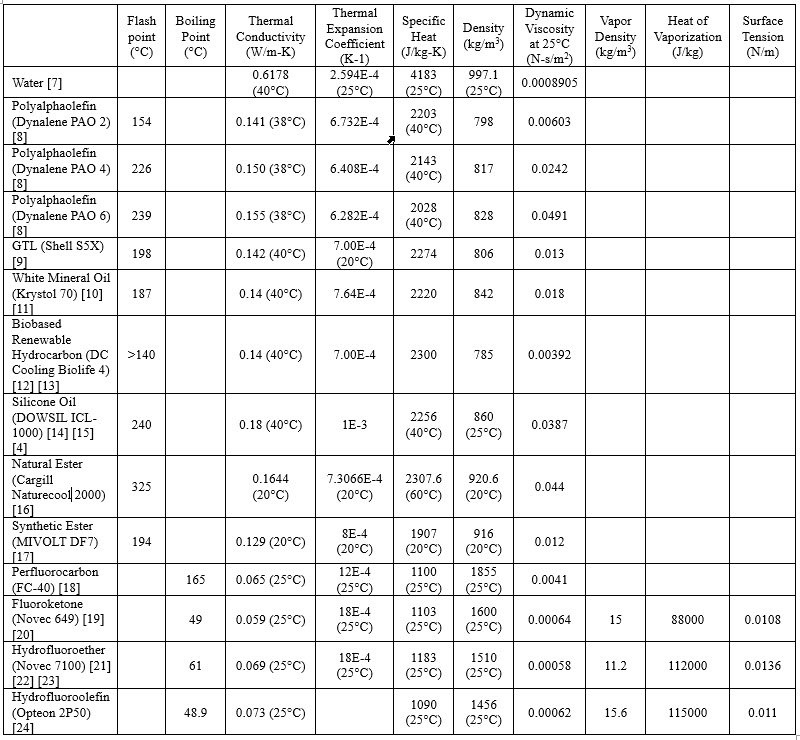

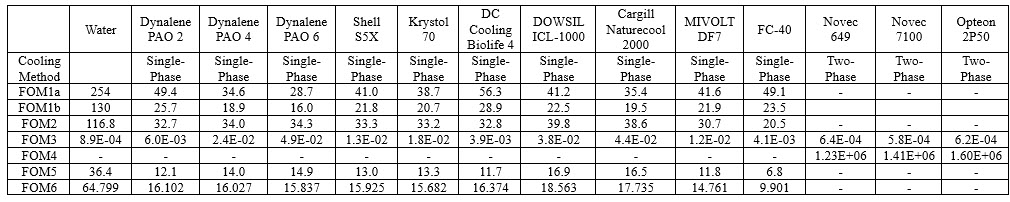

The thermal performance of immersion fluids can be evaluated using figures of merit (FOM). The OCP Base Specification for Immersion Fluids rev1. v1. outlines four FOM: FOM1 (denoted FOM1a) for natural convection of single-phase immersion fluids, FOM2 for forced convection of single-phase immersion fluids, FOM3 for viscosity (as a measure of pressure drop), and FOM4 for the heat transfer effectiveness during pool boiling (the boiling that occurs at the surfaces of submerged components) of two-phase immersion fluids. Incropera [4] provides FOMs for natural convection and forced convection (denoted as FOM1b and FOM5, respectively). Simons [6] also gives a FOM for forced convection under developing laminar flow (FOM6). Table 1 shows the fluid properties of common immersion coolants that were used to determine FOMs for each fluid in Table 2. FOM1a, FOM2, FOM3, and FOM4 have target specifications to adhere to as explained below.

Table 1: Thermophysical Properties of some Data Center Immersion Coolant Chemistries (water is included as a reference).

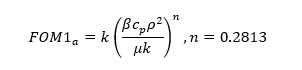

- FOM1 (natural convection for single-phase immersion) – Natural convection, energy transfer through a fluid without external forces, is the dominant heat transfer mechanism in an immersion tank [3]. Two FOMs are considered here for natural convection.

a) Natural convection for single-phase immersion [1] – considers fluid properties that affect heat transfer coefficient. A FOM1 score greater than 35 is considered a Tier 1 fluid, and a score greater than 45 is a Tier 2 fluid. Tier 2 fluids provide better heat transfer but may cost more.

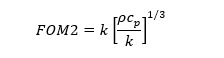

k = thermal conductivity (W*m-1*K-1)

β = thermal expansion coefficient (K-1)

cp = specific heat capacity (J*kg-1*K-1)

ρ = liquid density (kg*m-3)

µ = dynamic viscosity (N*s*m-2)

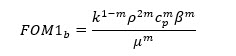

b) Natural convection in laminar flow [4] – the values of m depend on the flow regime. For laminar flow, m = 0.25 and for turbulent flow, m = 0.33. Laminar flow (m = 0.25) is applied for this FOM calculation in Table 2.

- FOM2 Forced convection for single-phase immersion [1] – Forced convection, energy transfer through a fluid due to motion generated by an external force, occurs by way of pumps in immersion cooling. A FOM2 score greater than 19 is acceptable. FOM2 does not account for the use of heat sinks, which is why fluorocarbons are scored low even though they transport heat well when used with high fin densities. It is equivalent to the heat transfer coefficient in forced convection laminar flow.

- FOM3 Viscosity for pressure drop [1] – Viscosity contributes significantly toward pressure drop, especially in laminar flow (assumed in FOM2), and pressure drop is a major consideration when sizing a pump. The spec target defines a maximum fluid viscosity of 1.5E-2 N*s*m-2 (15cP).

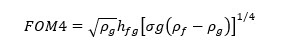

- FOM4 Pool boiling for two-phase immersion [1] – Pool boiling is applicable for two-phase immersion, where the fluid at the heat transfer surface moves due to free convection and the mixing caused by bubble formation and detachment [5]. A score greater than 1.1E6 is acceptable.

ρg = vapor density (kg*m-3)

ρf = liquid density (kg*m-3)

hfg = heat of vaporization (J*kg-1)

σ = surface tension (N*m)

g = gravitational acceleration (9.81 m*s-2)

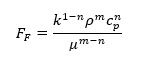

- FOM5 Forced convection laminar flow [4] – the values of m and n depend on the flow regime. For laminar fully developed internal flow in a tube, m = n = 0. For laminar external flow over a flat surface, m = 0.5 and for turbulent flow, m = 0.8. Most values of n range from 0.33 to 0.4. In the case of developing internal laminar flow as is considered for forced convection FOMs in this article, n is taken to be 0.33 and m is 0.25.

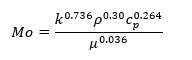

- FOM6 Developing internal laminar flow in heat sink microchannels [6] – the following equation is applicable to developing laminar flow regimes in microchannels where the thermal length (L/D / RePr) lies between 0.0005 and 0.0013.

Table 2: FOMs for some Data Center Immersion Coolant Chemistries (water is included as a reference)

It is important to take a holistic approach when using FOM for heat transfer and the rest of the properties discussed. In natural convection, heat transfer is more dependent on viscosity than in forced convection, as seen by the improvement of more viscous silicone oils and natural esters from FOM1 to FOM2. The flashpoint is important to note for single-phase immersion coolants since oils with higher flashpoints generally have higher viscosities, which will impact FOM comparisons. An example is the biobased renewable hydrocarbon, which has a low viscosity and flashpoint compared to the other hydrocarbon oils listed (PAO, GTL, and white mineral oil), giving it a higher FOM1 than even the PFC. There is not a one-size-fits-all solution and the choice of coolant is largely dependent on equipment compatibility, safety, and cost.

References

- Open Compute Project. (2022, December 1). Base Specification for Immersion Fluids. https://www.opencompute.org/documents/ocp-base-specification-for-immersion-fluids-20221201-pdf

- Bunger, R. & Lin, P. (2023, December 18). Comparison of Dielectric Fluids for Immersive Liquid Cooling of IT Equipment. Schneider Electric. https://www.se.com/us/en/download/document/SPD_WP291_EN/

- Submer (n.d.). Single-Phase Immersion Cooling: The Path to 1000W TDP & Beyond. https://submer.com/business-cases/forced-convection-heat-sink-with-intel/#:~:text=Natural%20convection%20stands%20as%20the%20primary%20mechanism,little%20impact%20on%20CPU%20and%20GPU%20temperatures.

- Incropera, F. P. (1999). Fluid Selection. In A. D. Kraus & A. Bar-Cohen (Eds.), Liquid Cooling of Electronic Devices by Single-Phase Convection (pp. 9-12). John Wiley & Sons, Inc.

- Faghri, A. & Zhang, Y. (2006). Boiling. Transport Phenomena in Multiphase Systems, 765-852. https://doi.org/10.1016/B978-0-12-370610-2.50015-5

- Simons, R. E. (2006, May 1). Comparing Heat Transfer Rates of Liquid Coolants Using the Mouromtseff Number. Electronics Cooling. https://www.electronics-cooling.com/2006/05/comparing-heat-transfer-rates-of-liquid-coolants-using-the-mouromtseff-number/

- Dincer, I. & Zamfirescu, C. (2016). Drying Phenomena: Theory and Applications (Appendix B). John Wiley & Sons, Ltd. https://onlinelibrary.wiley.com/doi/pdf/10.1002/9781118534892.app2

- Dynalene, “Dynalene PAO Series,” Data Sheet, Mar. 2025. https://www.dynalene.com/wp-content/uploads/2025/03/Dynalene-PAO-series-Tech-Data-Sheet-Rev0-1-1.pdf

- Shell, “Shell Immersion Cooling Fluid S5X,” Data Sheet, n.d. https://industrialfluidsmfg.twinoils.com/Asset/Shell%20Immersion%20Cooling%20Fluid%20S5%20X.pdf

- Azarifar, M., Arik, M., & Chang, J. -Y. (2024) Liquid Cooling of Data Centers: A Necessity Facing Challenges. Applied Thermal Engineering, 247, 123112. https://doi.org/10.1016/j.applthermaleng.2024.123112

- Krystol 70; SDS No. 000003000976 [Online]; Petro-Canada Emerica Lubricants LLC: Dallas, TX, Mar 3, 2024. https://petrocanadalubricants.com/api/sitecore/LubesApi/DownloadResourceV2?docID=krstl7&type=MSDS&lang=englishus

- TotalEnergies (n.d.). DC COOLING BioLife: 100% Biosourced Single Phase Dielectric Fluid. https://specialfluids.totalenergies.com/en/dc-cooling-biolife

- DC COOLING BIOLIFE 4; SDS No. C3DPQMBPG [Online]; TotalEnergies Fluids: Paris La Défense Cedex, France, Apr 26, 2023. https://cdn.toxicdocs.org/jB/jB7gObg4zXj87n6vqOzKjMYx9/jB7gObg4zXj87n6vqOzKjMYx9.pdf

- Dow, “DOWSILTM ICL-1000 Fluid,” Data Sheet, n.d. https://www.dow.com/en-us/document-viewer.html?docPath=/content/dam/dcc/documents/11/11-4298-01-dowsil-icl-1000-fluid.pdf

- DOWSILTM ICL-1000 Cooling Fluid; SDS No. 99194694 [Online]; The Dow Chemical Company: Midland, MI, Mar 21, 2023. https://www.dow.com/en-us/doc-viewer-blank.html?docType=SDS&contentType=SDS&product=518191z&tradeProduct=000000518191&selectedCountry=US&selectedLanguage=EN&recordNumber=47467619&title=DOWSIL%E2%84%A2%20ICL-1000%20Cooling%20Fluid-Safety%20Data%20Sheet-EN&useRequestPath=true

- Cargill, “Cargill NatureCoolTM 2000 Immersion Cooling Fluid,” Data Sheet, n.d. https://www.cargill.com/doc/1432215338811/naturecool-2000-pdf.pdf

- Mivolt, “DF7 Dielectric Liquid,” Data Sheet, Mar. 2024. https://www.mivolt.com/wp-content/uploads/2021/10/MIVOLT-DF7-Brochure_Mar23.pdf

- 3M, “Data Center Immersion Cooling Applications with 3MTM FluorinertTM Electronic Liquids,” Data Sheet, n.d. https://multimedia.3m.com/mws/media/1783283O/data-center-immersion-cooling-aplications-with-3m-fluorinert-electronic-liquids-line-card.pdf

- 3M, “3MTM NovecTM 649 Engineered Fluid,” Data Sheet, Sep. 2009. https://multimedia.3m.com/mws/media/569865O/3m-novec-engineered-fluid-649.pdf

- 3MTM NovecTM 649 Engineered Fluid; SDS No. 19-2786-2 [Online]; 3M Canada Company: London, Ontario, May 3, 2022. https://multimedia.3m.com/mws/mediawebserver?mwsId=SSSSSuUn_zu8lZNU4Y_voYtBMv70k17zHvu9lxtD7SSSSSS–

- TMC Industries. 3M NOVECTM 7100. https://tmcindustries.com/products/3m_novec_7100?srsltid=AfmBOopw-wQXOdhwILllDWAIsZv4dn5BweFFAc9gqeOjrub0MlBJV0ew

- 3M, “Data Center Liquid Cooling Applications with 3MTM NovecTM Engineered Fluids,” Data Sheet, Feb. 2020. https://multimedia.3m.com/mws/media/1801351O/data-center-immersion-cooling-aplications-with-3m-novec-engineered-fluids-line-card.pdf

- 3MTM NovecTM 7100 Engineered Fluid; SDS No. 07-6378-9 [Online]; 3M: St. Paul, MN, Apr 12, 2023. https://multimedia.3m.com/mws/mediawebserver?mwsId=SSSSSuUn_zu8l00xl8mBm8mePv70k17zHvu9lxtD7SSSSSS–

- Opteon, “OpteonTM 2P50 Developmental Heat Transfer Fluid,” Data Sheet, n.d. https://www.opteon.com/en/-/media/files/opteon/opteon-2p50-gic-product-info-sheet-fnl-100523.pdf?rev=97280bc88a2c4f698d3ec07551a6ac01